At MetalTech, we’ve developed practices to ensure we deliver turn-key solutions at cost-effective rates for our clients. We source metals and castings from domestic and international suppliers and auditing facilities based on their capabilities and quality control. With a network of 70+ audited overseas partners, including foundries, heat treating facilities, painting facilities, engineering resources, and forging companies spanning Taiwan, Saudi Arabia, Dubai, and India, we offer a diverse range of materials, from gravity die-casting to steel forging and brass foundry services. Working with MetalTech means you’re tapping into a vast array of global resources.

We’ve fine-tuned our business model over 40 years to maintain a reliable supply chain, making it supply chain director-friendly. We employ our exclusive JIT (Just-In-Time) inventory program, utilizing consignment and wholesale retail agreements to optimize our stock levels allowing us to get you the products you need. We maintain a regular dialogue with our customers through monthly meetings, either virtually or in person, ensuring we always have a clear understanding of their requirements. Every component we supply is 100% OEM, including foundry services, and our dedicated sourcing team at MetalTech USA comprises cross-trained experts who can seamlessly handle both technical and commercial aspects of the sourcing process. Our team’s ability to step in for one another ensures a dependable and agile supply chain.

Sourcing

Over the past several decades, our strategic sourcing practices have been the bedrock of a reliable supply chain, delivering high-quality materials at competitive rates to our clients. We’ve built a network of 70+ domestic and international partners, each audited by our experienced team to ensure their capabilities and quality meet our stringent standards. These partners offer a diverse range of materials and foundry services, encompassing gravity die-casting, steel forging, brass foundry, and more. When you choose to source with us, you gain access to a wealth of global resources that cater to your specific material requirements.

Utilizing Just-In-Time (JIT) principles, we streamline our stock levels through consignment and wholesale retail agreements, assuring the timely delivery of materials. Monthly meetings with our clients, whether in person or virtually, maintain clear lines of communication, guaranteeing we always understand your evolving needs. This open dialogue allows us to be well-prepared to provide you with high-quality materials and foundry services promptly and efficiently.

Our sourcing team at MetalTech is composed of cross-trained experts, showcasing our adaptability and experience in the sourcing field. They proficiently manage both the technical and commercial aspects of the sourcing process, ensuring a reliable and flexible approach to meet your specific sourcing needs. When it comes to materials and foundry services, you can rely on our dedicated team to be your trusted partner for sourcing.

Grinding

At MetalTech, we’re experts at the craft of casting grinding. We have redefined the labor-intensive grinding processes into highly efficient and profit-yielding operations. In the world of foundries, where precision and profitability are paramount, our grinding expertise consistently delivers, often resulting in doubling or even tripling our clients’ revenue.

We use various techniques, including precision profiling, surface grinding, flash and gate removal, and surface finishing; we provide exactly what our clients need. Our approach helps foundries eliminate bottlenecks in the cleaning room, helping you do what you do best: making money.

When you choose MetalTech for grinding, you’re not just selecting a service; you’re entering a partnership with experts. We’re dedicated to boosting your profitability through cleaning castings, helping your bottom line.

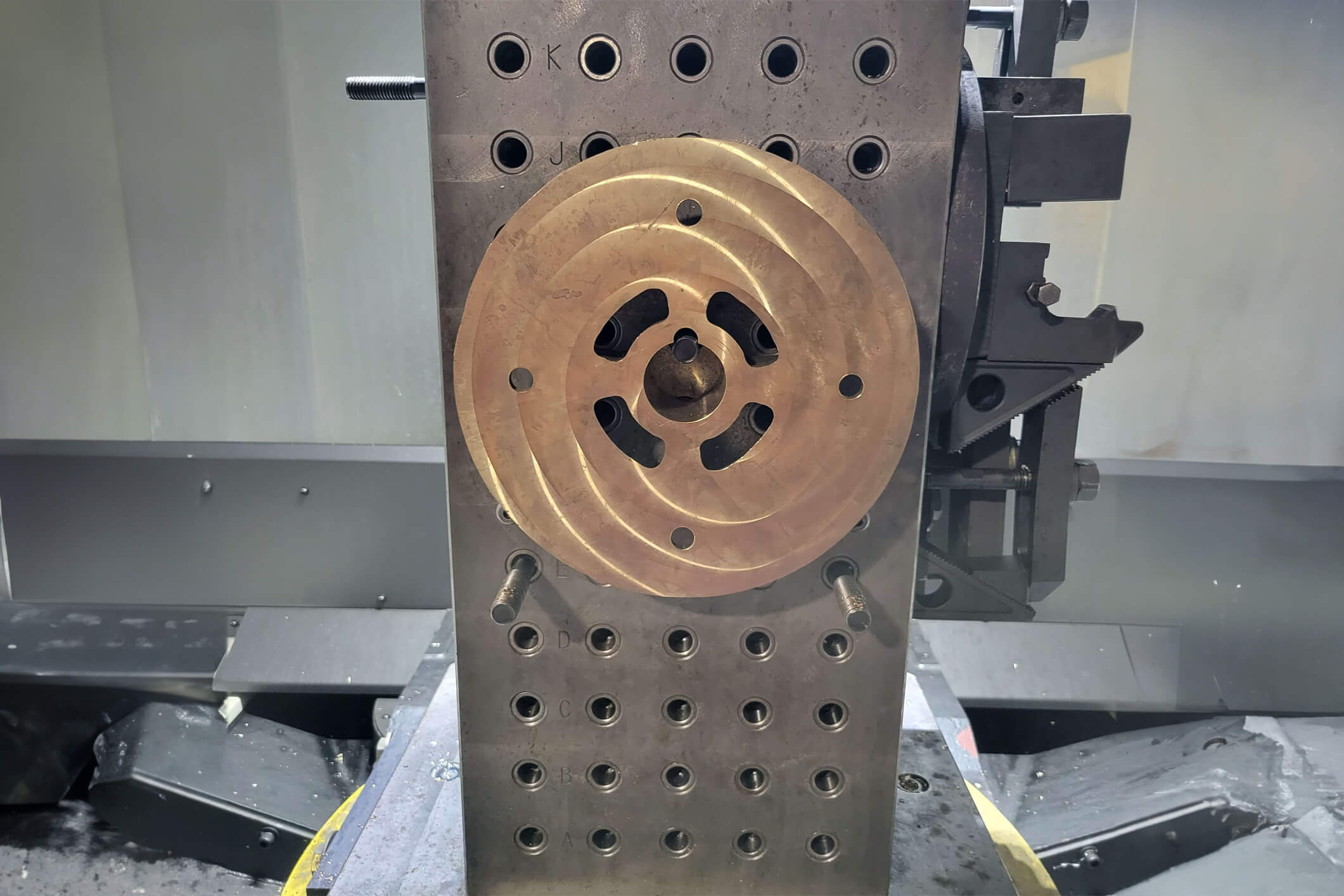

Finish Machining

At MetalTech, we understand that our clients’ needs go beyond conventional services. Finish Machining is crucial in various industries and applications where precision and quality are essential. We offer comprehensive turn-key finish machining services to ensure that components are finely tuned and precisely finished, meeting specific industry requirements.

To achieve superior finish machining results, we utilize advanced technologies and equipment. Our approach combines technical expertise with a deep understanding of the commercial aspects of the business. We’re committed to educating our customers about the possibilities of finish machining because we believe that informed decision-making leads to better results.

We take pride in our niche expertise, bridging the gap between casted and machined components. Our dedication to finding innovative turn-key solutions for our clients is at the core of what we do. Whether it’s turning steel weldment jobs into ductile castings or guiding customers who may not be aware of the full spectrum of possibilities, MetalTech is always focused on improving efficiency and delivering quality results. While we excel in a range of finish machining tasks, some aspects of the process, such as painting, galvanizing, and powder coating, are outsourced to our trusted partners who share our commitment to excellence.

We believe that the sky is the limit for industrial America! When you partner with us for Finish Machining, you’re choosing a team that is dedicated to helping you explore new avenues for success.

Weldment to Casting

At MetalTech, we excel in the intricate process of transforming weldments into castings. By combining reverse engineering, state-of-the-art 3D printing, and open communication with engineers and customers, we unlock a host of advantages. This shift addresses the limitations of weldments, known for their labor-intensive nature, variations, and hidden weaknesses caused by heat-induced warping during welding. We offer solutions for your business. Our castings allow for improved repeatability, precise conformance, and enhanced quality, effectively overcoming these challenges.

This transformation from weldments to castings is driven by the need to overcome the limitations of weldments. Weldments are notorious for being labor-intensive and prone to variation from one piece to another, making it challenging to maintain consistent quality. Often, the weaknesses inherent in weldments remain hidden until it’s too late, resulting in costly repercussions. The welding process introduces heat, causing metal to warp and further complicating efforts to ensure uniform quality.

The transition to castings ensures superior structural integrity, design flexibility, consistent quality, and reduced production costs, offering clients a more reliable and cost-effective alternative. At MetalTech, our commitment to this transformation reflects our dedication to providing clients with efficient and precision-focused solutions.